Glass curtain walls are a common exterior wall design in modern buildings. They make the building look transparent and bright, full of futuristic feeling. But did you know? These glass curtain walls are actually composed of multiple parts. From the supporting skeleton to the glass panel, from the waterproof seal to the intelligent control system, each part has its own role, and together they ensure that the glass curtain wall is both beautiful and safe. Zhongdong Curtain Wall will lead you to understand the components of glass curtain walls today.

1. Glass curtain wall skeleton structure: the “skeleton” of the curtain wall

If the glass curtain wall is compared to the human body, the skeleton is its “skeleton”, which is responsible for supporting the weight of the entire curtain wall and ensuring that the glass panel is firmly fixed on the exterior wall of the building.

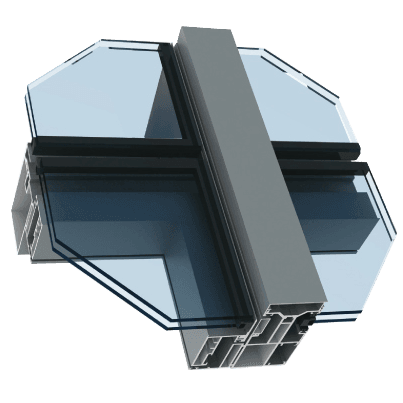

1. Metal frame

The most common skeleton material is aluminum alloy, because it is light, not easy to rust, and can be molded into various shapes. The frame is usually composed of horizontal and vertical metal strips (called “beams” and “columns”) to form a grid structure. For example, the entire glass wall you see in the mall is silently supported by these metal strips behind it.

Why not use steel?

Although steel is stronger, it is too heavy and easy to rust. Although aluminum alloy has a slightly lower strength, it can also meet the needs through thickening or special design.

2. Special support structure

For curtain walls with very large areas (such as airports or stadiums), ordinary frames alone may not be enough. At this time, engineers will use steel cables, steel frames or even pull rods to strengthen the support.

2. Glass panel: the “skin” of the curtain wall

Glass is the most conspicuous part of the curtain wall, but its role is far more than “light transmission”. Different types of glass can insulate heat, sound, and even generate electricity!

1. Basic glass types

Tempered glass: Ordinary glass becomes stronger after high-temperature treatment. Even if it breaks, it will break into small particles, reducing the risk of injury.

Laminated glass: A layer of film is sandwiched between two layers of glass. Even if it breaks, it will not fall off. It is often used in high-rise buildings or skylights.

Insulating glass: There is a gap between the two pieces of glass and filled with inert gas (such as argon), which can effectively insulate heat and sound. For example, it is used to prevent indoor heating from dissipating in winter.

2. Coated glass

Modern curtain walls are becoming more and more “smart”. There is a kind of glass with a special coating (low-emissivity coating, referred to as Low-E) on the surface, which can reflect sunlight heat in summer and retain indoor temperature in winter. The more advanced “electrochromic glass” can adjust the transparency like a chameleon, and the glass can be darkened by pressing a button, replacing curtains.

3. Sealing material: the “glue” of curtain wall

The gap between glass and frame is not perfect, and sealing materials are needed to fill the gap to prevent rain, dust and even noise from getting in.

1. Rubber strips and sealants

Rubber strips: installed on the edge of the frame, wrapping the glass like a cushion, playing a buffering and preliminary waterproofing role.

Structural glue: a strong adhesive that firmly sticks the glass to the frame. It must be resistant to high temperatures and aging, otherwise it will be troublesome if it cracks after a few years.

2. Hidden waterproof design

There are actually clever drainage channels inside the curtain wall. Even if a small amount of rainwater seeps in, it will flow to the outside through the designed path and will not wet the indoor wall. This is like installing an “invisible water pipe” for the curtain wall.